Whisky “Boilers” Galore

Allen Associates have been involved in over 20 malt whisky distillery boiler projects throughout Scotland. It was this experience together with process design expertise that led to John Dewars & Sons appointing Allen Associates as the design engineers and project managers for the new boiler project at Macduff Distillery.

The Project

The existing boilers at MacDuff Distillery were due for replacement and the boiler house location was not ideal for maintenance access.

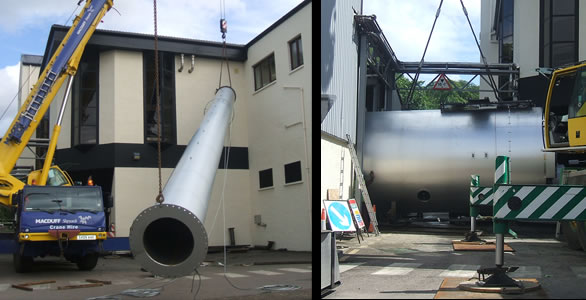

Allen Associates carried out a design study for a new boiler house which concluded that a new single boiler with capacity 35,000 lb/h should be installed in the redundant filling store. The new boiler was sized to meet current steam demand and also potential future demand.

Installing the boiler in the filling store meant a new purpose built boiler house could be designed and also the installation of the boiler could be carried out whilst the distillery was operating. The project also made the existing boiler house available for future use as an extended tun room if production was to be increase at MacDuff.

In addition to a new boiler a new chimney and steam system was designed and installed by Allen Associates.

Results

To aid the approval of capital for the project Allen Associates carried out a justification exercise.

The benefits of installing the new boiler were;

- improved reliability

- increased energy efficiency

- reduced environmental impact

- compliance with relevant legislation

- improved health and safety

The operating savings associated with the installation were estimated at £47,500 per annum

The new boiler project at Macduff was a success and converting the redundant filling store into a new boiler gave added benefits. It is this ability for Allen Associates to see the bigger picture and ensure that you do the “right project” that sets us apart from others.