Hillington Vat Room Package Supply

Client: Douglas Laing & Co.

Location: Hillington, Glasgow

Services: Package supply of purpose-built vatting system and associated operations

Overview

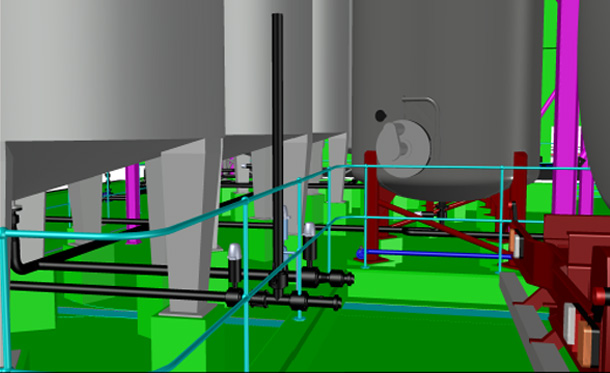

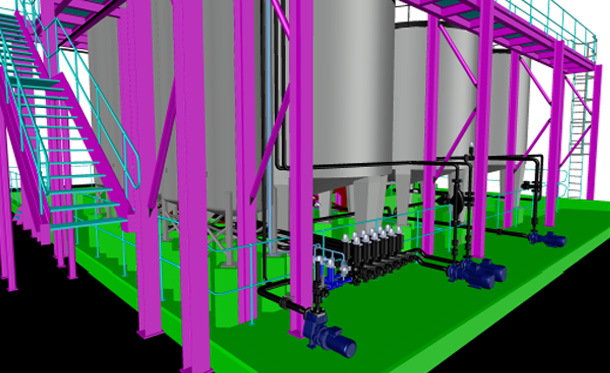

Allen Associates were tasked with delivering a complete package supply solution for Douglas Laing’s purpose-built vat room at their Hillington facility, covering the full spectrum of blending and whisky handling operations.

Scope of Work

- Blending Operations: Design and integration of blending vessels and systems for consistent and high-quality batches.

- Cask Filling & Disgorging: Provision of automated cask filling and disgorging systems.

- Whisky Preparation for Bottling: Equipment and processes to transfer single malt or blend into readiness for bottling lines.

- Bulk Spirit Handling: Design of tanker unloading systems for safe and efficient receipt of spirit deliveries. Integration of tanker filling capabilities for dispatching blended whisky back to tanks for onward logistics.

- Package supply: End-to-end responsibility—from conceptual process design through equipment specification and supply—ensuring seamless installation and commissioning.

Results & Benefits

- Streamlined Project Delivery: With Allen Associates managing both design and supply, Douglas Laing received a single point of accountability for project delivery.

- Operational Efficiency: Tailored engineering and automation improved workflow between blending, handling, and bottling operations.

- Quality and Compliance: Systems were designed with distilled spirits in mind—ensuring process safety compliance, batch integrity and minimal product loss.

- Future Flexibility: Modular equipment design allows Douglas Laing to adapt to increasing volumes or operational changes with minimal reconfiguration.