iCask™ System – A Bespoke Solution to all your Post Distilling Requirements

We realised that the industry would benefit from a process and recording system which was flexible enough to meet the ever increasing demands of Craft Distillers for cask operations post distilling. Using our expertise and experience we have developed a unique modular based system which can be customised to meet Customers’ exact requirements.

The Project

With the increase in number of variants of whiskies offered by distillers (special editions, singe cask bottlings, wood finishes, strengths, exclusive blends etc), the processes needed post distilling, including accounting and reporting requirements for HMRC, need to be considered at an early stage in design. Allen Associates, recognising this need, have developed a modular system, iCask™, which allows distillers to install a system which is flexible enough to meet their requirements as their business develops.

Each system can be designed to suit the clients requirements, however a typical installation comprises of the following four modules:

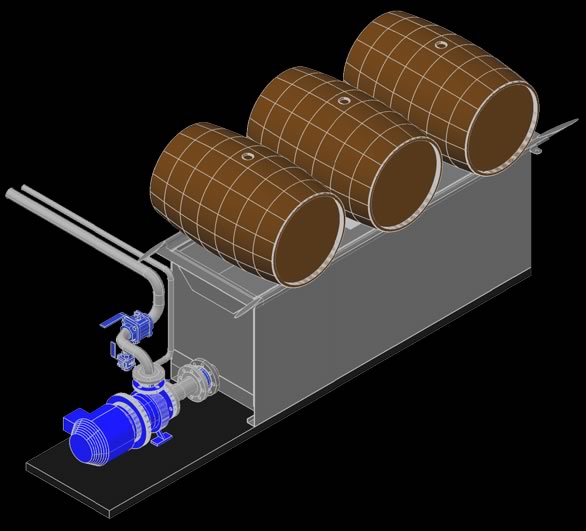

- A process tank (SRWV) on load cells and with other instrumentation, recirculation, transfer pump and associated pipework. This allows for a variety of operations from a single multi-use vat e.g. cask filling, cask disgorging, spirit reduction for cask filling or bottling, blending, colour or flavour additions.

- A cask conveyor system including a loading or unloading point on load cells, which is either powered or unpowered.

- Cask filling and cask disgorging system. The disgorging system will have mature spirit filtration installed as standard.

- A recording system so that all spirit transfers can be recorded and reported for HMRC purposes.

The team designed the system using a modular approach, which allows:

- units to be fabricated and assembled quickly, and tested prior to delivery

- rapid installation and commissioning

- easy transportation - the unit can be moved in a standard trailer

- additional modules to be easily added on to increase capacity

With vessel sizes ranging from 1,000 litres, working with the customer, Allen Associates process engineers and designers can develop a bespoke system to meet all the projected requirements in as an efficient way possible.

Results

Allen Associates iCask™ system provides a fast, flexible and cost effective solution to the post distilling process which is crucial for craft distillers. It means craft distillers can install a bespoke system from day 1 which will offer the flexibility to meet their varying needs while they develop their markets and products, and meet HMRC reporting requirements.