Leading the Design of Islay’s New Distilleries

Client: Various

Location: Islay, Scotland

Projects: Ardnahoe, Islay Rum, Laggan Bay, Portintruan

Services: Full Process and Utility Design, Engineering Support

Overview

Islay has long been synonymous with world-renowned peated whiskies and a deep-rooted distilling heritage. In recent years, a new chapter has begun on the island, marked by a wave of investment in modern distillery developments. Of the five major new distillery projects underway or recently completed on Islay, Allen Associates (HPE) Ltd has played a pivotal role in designing four: Ardnahoe, Islay Rum, Laggan Bay, and Portintruan.

Each of these projects has its own vision and ambition — whether that’s producing classic peated single malts, bringing rum production to the island for the first time, or creating high-efficiency, future-ready facilities. Allen Associates was chosen for their deep technical knowledge, practical delivery, and track record of working with both large global brands and independent ventures..

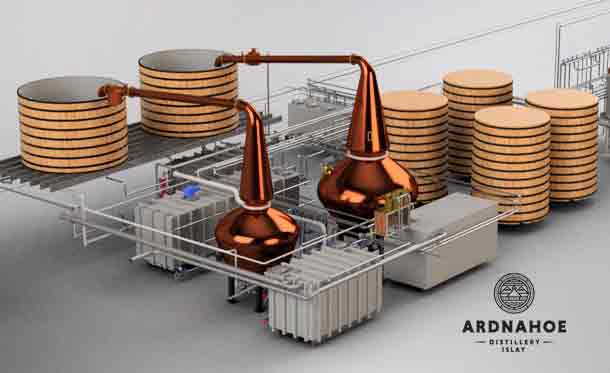

ARDNAHOE DISTILLERY

Client: Hunter Laing & Co.

- Delivered complete process design including mash house, fermentation, and traditional twin stills.

- Integrated worm tub condensers – a rare feature in new designs that contributes to a heavier spirit profile.

- Balanced heritage and modern safety/environmental standards for a scenic, visitor-ready site.

ISLAY RUM

- The first rum distillery on the island, bringing fermentation and distillation expertise beyond whisky.

- Allen Associates designed a bespoke batch fermentation and double retort pot distillation system for small-scale, high-quality rum production.

- Supported startup through commissioning and fine-tuning of process control and energy usage.

LAGGAN BAY DISTILLERY

Client: Ian MacLoed Distillers (in costruction)

- Large-scale peated malt whisky facility designed with energy efficiency and maximising space through intelligent design in mind.

- Allen Associates provided full process and utility system design, including heat recovery which consisted of a thermal vapour recompression system and condenser hot water recovery integration.

- The design included considerations for long-term sustainability and reduced environmental impact.

PORTINTRUAN DISTILLERY

Client: Elixir Distillers (currently under construction)

Portintruan is a landmark project — an intricate distillery that seamlessly blends traditional whisky-making methods with cutting-edge process design.

Key highlights of the project include:

- Traditional meets modern: Direct-fired stills are integrated with advanced condenser heat recovery systems to maximise energy efficiency without compromising character.

- Maltings integration: A new on-site maltings facility is directly linked to the condenser hot water recovery system, creating a highly efficient energy loop across the site.

- Full-scope process engineering: Allen Associates delivered the complete process engineering design, equipment specifications, HAZOP facilitation, and implementation support.

- Operational flexibility: The distillation systems for both wash and spirit allow for multiple configuration modes, offering exceptional flexibility in production.

- World-leading design: This is arguably the most sophisticated and feature-rich malt whisky distillery ever built. While we won’t pre-empt our client’s official unveiling, suffice to say — this facility will amaze.

- Unmatched expertise: Allen Associates was uniquely positioned to deliver a project of this complexity. Every team member involved has over a decade of distilled spirits process engineering experience, making us one of the only consultancies capable of executing a project at this level.

Scope of Services Across Projects

Across the four distilleries, Allen Associates provided:

- Process Design - from mashing, fermentation, and distillation to spirit storage and by-product handling

- Heat recovery design - condenser hot water recovery, TVR, maltings integration.

- Utility Design - including steam, cooling, air, CIP systems, and energy recovery

- Equipment Specification and Sourcing - from custom copper stills to pumps, valves, and controls

- HAZOP and Safety Reviews - ensuring designs met process safety and compliance standards

- Start-up & Commissioning Support - both remotely and on-site

- Sustainability Focus - including water reuse, heat recovery, and energy performance analysis

Outcomes

These projects demonstrate Allen Associates' central role in shaping the next generation of distilling on Islay. Each design has been tailored to meet the client's production vision, site constraints, and long-term operational goals, while aligning with the unique heritage and environmental context of the island.

Through trusted relationships, deep process understanding, and a strong practical engineering approach, Allen Associates continues to be the go-to design partner for innovative distillery developments – both on Islay and beyond.